Current Location:Home >Product > briquette machine > >

Welcome to our factory,test samples for free,Complete machine models!Immediately consult

【Feed particle size】<10mm

【Processing power】5.5kw-110kw

【Application field】:Widely used in refractories, power plants, metallurgy, chemicals, energy, transportation, heating, animal husbandry, industry, agriculture, barbecue and other fields.

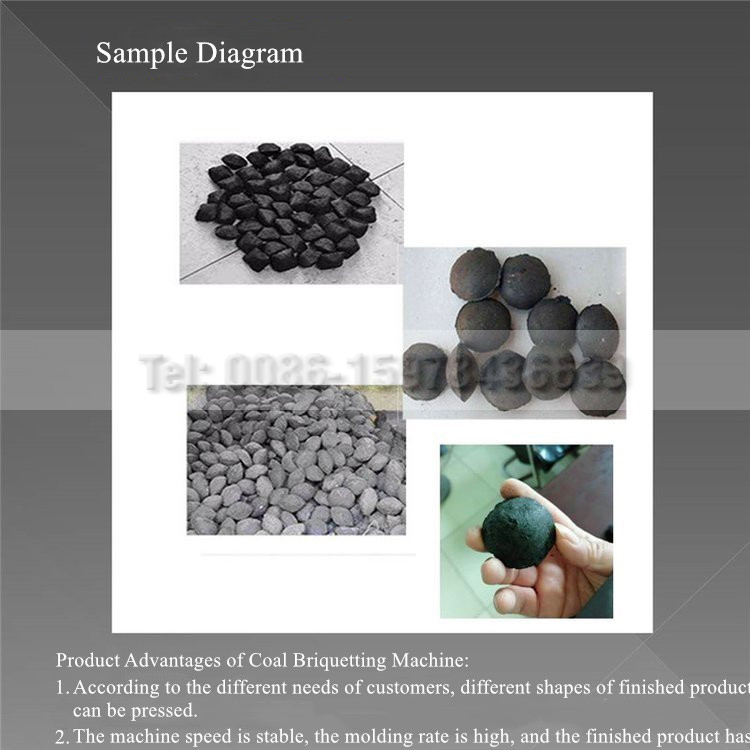

【For the material】:Charcoal powder, carbon powder, bamboo carbon powder, coke powder, shisha carbon, graphite powder, shell carbon, jujube charcoal, blue charcoal powder, activated carbon and other powder materials, powder materials, waste materials.

Enquiry and Investigation Hotline:

0086-15978436639

| Model | Reducer | Ratio | Roller Size (mm) | Main Shaft Speed (r/min) | Matched Power (kw) | Capacity (t/h) | Pressure Type |

| XM290 | ZQ350 | 1:31.5 | 290*200 | 12-14 | 5.5 | 0.9-1.0 | Mechanical |

| XM360 | ZQ350 | 1:31.5 | 360*250 | 12-14 | 7.5 | 1.5-2.0 | Mechanical/Hydraulic |

| XM400 | ZQ400 | 1:31.5 | 400*250 | 12-14 | 7.5 | 2.5-3.5 | Mechanical/Hydraulic |

| XM430 | ZQ400 | 1:31.5 | 430*250 | 12-14 | 11 | 3.5-4.5 | Mechanical/Hydraulic |

| XM500 | ZQ650 | 40.17 | 500*470 | 10-12 | 37 | 7.5-8.5 | Mechanical/Hydraulic |

| XM650 | ZQ850 | 40.17 | 650*470 | 9-11 | 45 | 9-10 | Mechanical/Hydraulic |

| XM750 | ZQ1000 | 48.57 | 750*570 | 9-11 | 90 | 13-14 | Mechanical/Hydraulic |

| XM850 | ZQ1250 | 50 | 850*570 | 8-10 | 110 | 15-17 | Mechanical/Hydraulic |

| Remarks | 1. Above capacity is based on coal density 0.8, briquette size Φ50*33mm. | ||||||

| 2. Roller material is 65Mn, High chromium alloy and 9Cr2Mo. | |||||||

| 3. According to different material, parameter will change slightly. | |||||||

If you are interested in buying or have questions about the product, please fill in your information here, we will contact you in time! Or call our service hotline:0086-15978436639