Current Location:Home >Product > briquette machine > >

Welcome to our factory,test samples for free,Complete machine models!Immediately consult

【Feed particle size】<10mm

【Processing power】5.5kw-110kw

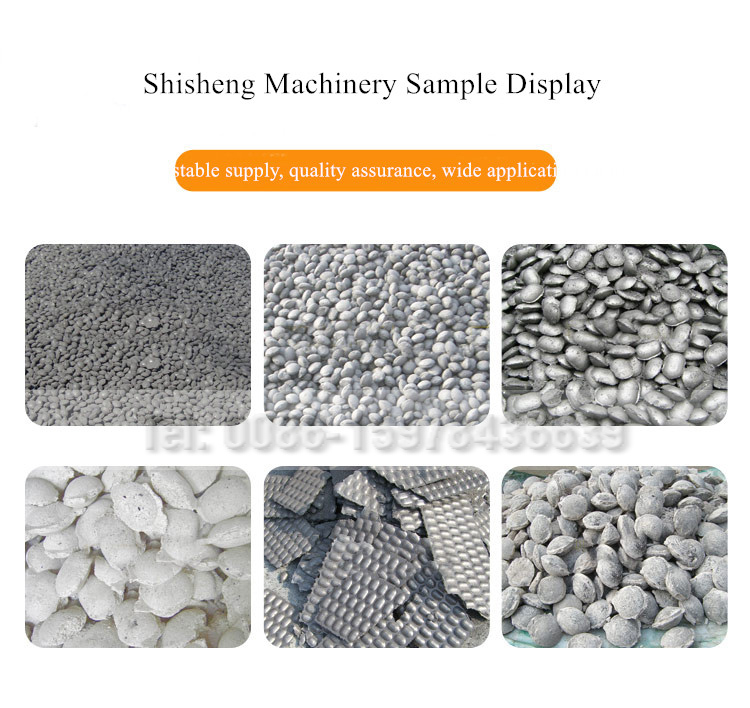

【Application field】:Widely used in refractories, power plants, metallurgy, chemicals, energy, transportation, heating and other industries。

【For the material】:Iron powder, slag powder, iron oxide scale, steel slag, refractory material, coal powder, coal slime, medium coal, coke pow

Enquiry and Investigation Hotline:

0086-15978436639

| Model | Reducer | Ratio | Roller Size (mm) | Main Shaft Speed (r/min) | Matched Power (kw) | Capacity (t/h) | Pressure Type |

| XM290 | ZQ350 | 1:31.5 | 290*200 | 12-14 | 5.5 | 0.9-1.0 | Mechanical |

| XM360 | ZQ350 | 1:31.5 | 360*250 | 12-14 | 7.5 | 1.5-2.0 | Mechanical/Hydraulic |

| XM400 | ZQ400 | 1:31.5 | 400*250 | 12-14 | 7.5 | 2.5-3.5 | Mechanical/Hydraulic |

| XM430 | ZQ400 | 1:31.5 | 430*250 | 12-14 | 11 | 3.5-4.5 | Mechanical/Hydraulic |

| XM500 | ZQ650 | 40.17 | 500*470 | 10-12 | 37 | 7.5-8.5 | Mechanical/Hydraulic |

| XM650 | ZQ850 | 40.17 | 650*470 | 9-11 | 45 | 9-10 | Mechanical/Hydraulic |

| XM750 | ZQ1000 | 48.57 | 750*570 | 9-11 | 90 | 13-14 | Mechanical/Hydraulic |

| XM850 | ZQ1250 | 50 | 850*570 | 8-10 | 110 | 15-17 | Mechanical/Hydraulic |

| Remarks | 1. Above capacity is based on coal density 0.8, briquette size Φ50*33mm. | ||||||

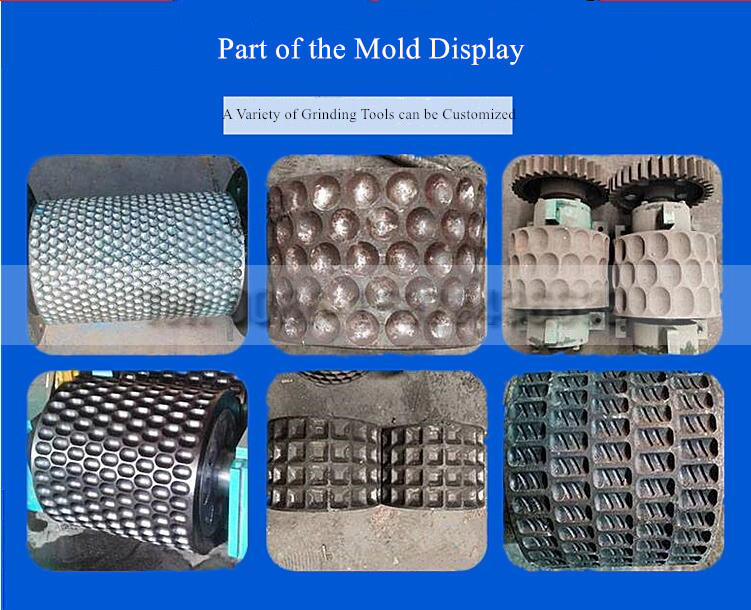

| 2. Roller material is 65Mn, High chromium alloy and 9Cr2Mo. | |||||||

| 3. According to different material, parameter will change slightly. | |||||||

If you are interested in buying or have questions about the product, please fill in your information here, we will contact you in time! Or call our service hotline:0086-15978436639